Solder Paste Shelf Life and Testing

Products

Introduction

Welcome to Luxury Ride Dubai's comprehensive guide on solder paste shelf life and testing. In this article, we will delve into the details of solder paste storage, its shelf life, and how to effectively test its viability. Whether you are a professional in the electronics industry or a hobbyist, understanding solder paste's properties and longevity is crucial for successful soldering projects.

Solder Paste Shelf Life

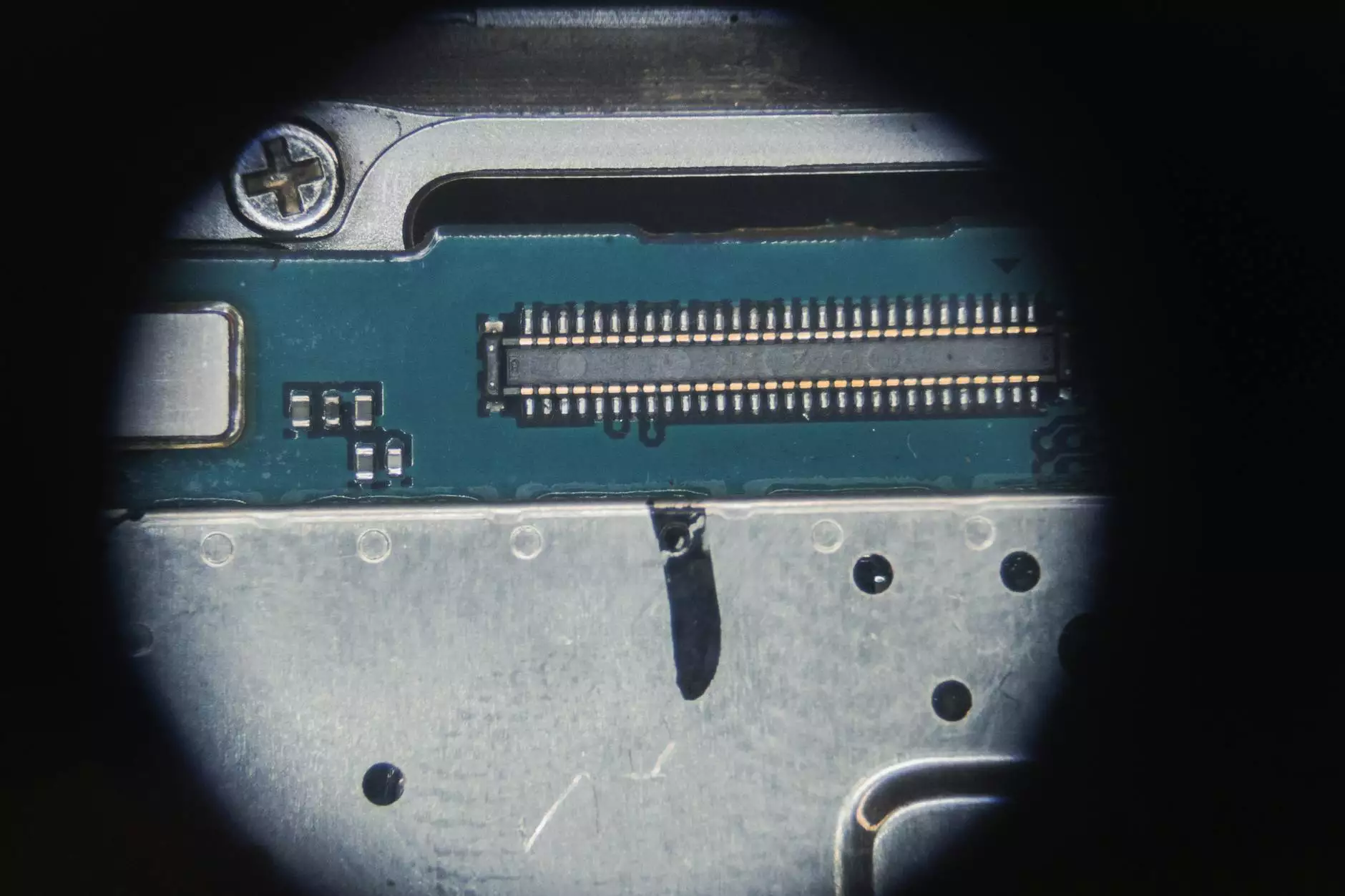

Before discussing the shelf life of solder paste, let's understand what solder paste is. Solder paste is a critical component in electronic assembly, composed of small metal alloy particles in a flux medium. It is commonly used for attaching electronic components onto printed circuit boards (PCBs) through the soldering process.

The shelf life of solder paste generally depends on several factors, such as the type of flux used and the storage conditions. Typically, most solder paste manufacturers provide a specified expiration date, which indicates the period during which the paste is guaranteed to perform optimally.

It is important to note that solder paste can degrade over time, which may lead to poor solder joint quality and potential reliability issues. To ensure the best results, adhere to the expiration date provided by the manufacturer.

Storage Conditions

Proper storage conditions play a vital role in extending the shelf life of solder paste. Here are some essential considerations for storing solder paste:

Temperature

Solder paste should be stored in a cool, dry place, away from direct sunlight and extreme temperature fluctuations. Generally, it is recommended to store solder paste between 5°C (41°F) and 10°C (50°F) to maintain its integrity. Avoid subjecting solder paste to high temperatures, as it can accelerate the aging process and reduce its shelf life significantly.

Humidity

High humidity can negatively impact solder paste, leading to oxidation of the metal particles and reduced solderability. Ensure that the storage area is low in humidity, ideally below 50% relative humidity. If necessary, consider using a dehumidifier to maintain the appropriate moisture levels.

Airtight Containers

When storing solder paste, it is crucial to use airtight containers to prevent exposure to moisture and air. Properly sealed containers, such as syringes or vacuum-sealed bags, help maintain the paste's freshness and delay the aging process.

Testing Solder Paste Effectiveness

Regularly testing the effectiveness of solder paste is essential to ensure high-quality solder joints and reliable electronic assemblies. Here are some widely used methods for testing solder paste:

Solderability Testing

Solderability testing involves measuring how well the solder paste wets and adheres to the solderable surfaces. This test assesses the paste's ability to form reliable solder joints. Various techniques, such as the solderability dip test and solderability spread test, can be employed to evaluate solder paste solderability.

Printability Testing

Printability testing determines the paste's ability to be accurately deposited onto PCBs. This testing ensures that the solder paste maintains proper viscosity, tackiness, and stencil release properties. It helps identify any issues in the printing process that may affect the soldering quality.

Reflow Performance Testing

Reflow performance testing evaluates the solder paste's behavior during the reflow soldering process. This test measures how the paste melts, flows, and forms solder joints under controlled thermal conditions. Monitoring aspects like wetting, voiding, and solder ball formation enables optimization of the reflow process parameters.

Conclusion

In summary, understanding the shelf life and testing requirements of solder paste is crucial for successful soldering projects. By following proper storage conditions and regularly testing the paste's effectiveness, you can ensure high-quality solder joints and reliable electronic assemblies. Remember to adhere to the manufacturer's expiration date and consider professional guidance when required. For more information on solder paste or other soldering-related topics, feel free to explore the Luxury Ride Dubai website.