Quick Tips & Techniques for PCB Assembly Inspection

Courses

Introduction

Welcome to Luxury Ride Dubai, your ultimate destination for luxury car experiences in Dubai. In this article, we will be discussing essential tips and techniques for effective PCB assembly inspection. Whether you are a beginner or an experienced professional, these insights will help you ensure the quality and accuracy of your PCB assembly process.

Understanding PCB Assembly Inspection

PCB assembly inspection plays a vital role in maintaining the integrity and functionality of electronic devices. It involves thorough visual inspection, testing, and verification of various components on a printed circuit board. Proper inspection techniques help identify defects, errors, and potential issues that may affect the overall performance and reliability of the PCB.

Importance of PCB Assembly Inspection

The importance of PCB assembly inspection cannot be overstated. It ensures that the finished product meets the required standards and specifications. Proper inspection can help detect and rectify errors early in the process, saving time and costs associated with rework and potential failure in the field. It also ensures compliance with industry regulations and enhances customer satisfaction.

Key Tips for Effective PCB Assembly Inspection

1. Establish a Standard Operating Procedure

Developing a comprehensive Standard Operating Procedure (SOP) for PCB assembly inspection is crucial. This document should outline step-by-step guidelines, including visual inspection techniques, testing procedures, and acceptance criteria. Adhering to a well-defined SOP ensures consistency and accuracy in the inspection process.

2. Train the Inspection Team

It is essential to invest in regular training and skill development for the inspection team. Familiarity with industry standards, IPC guidelines, and emerging technologies will enable the team to identify potential defects accurately. Ongoing training ensures that inspectors are up-to-date with the latest trends and techniques in PCB assembly inspection.

3. Utilize Advanced Inspection Equipment

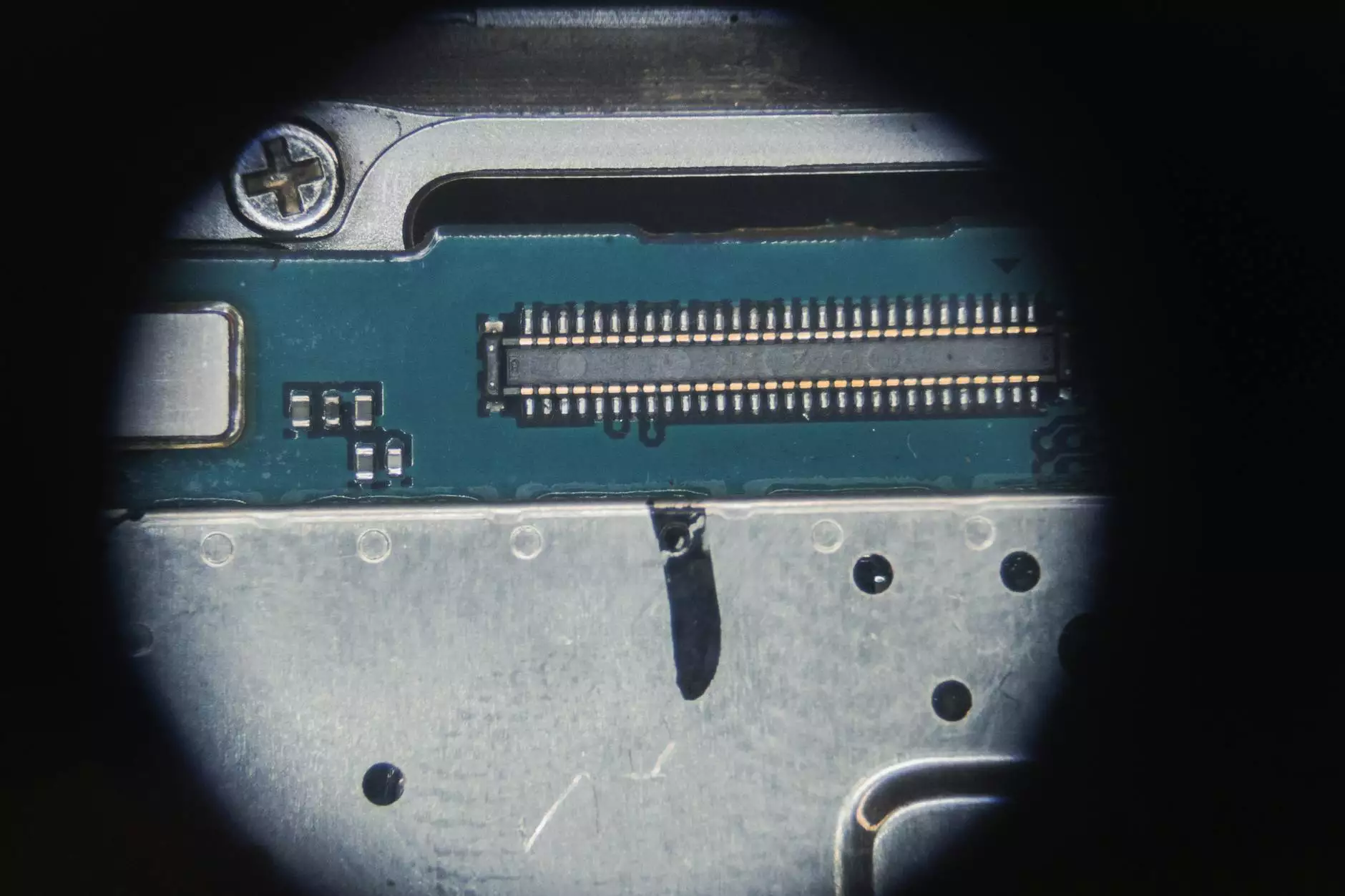

Quality inspection equipment plays a pivotal role in accurate PCB assembly inspection. Utilizing advanced tools such as automated optical inspection (AOI) systems, X-ray systems, and solder paste inspection (SPI) machines can enhance defect detection capabilities. These technologies offer high precision, speed, and reliability, enabling efficient inspection of complex PCB assemblies.

4. Implement Regular Quality Control Audits

Regular quality control audits are essential to assess the effectiveness of your PCB assembly inspection process. These audits involve evaluating inspection results, identifying trends, and implementing corrective actions. Conducting periodic audits helps identify areas for improvement and ensures that inspection procedures align with industry best practices.

5. Emphasize Component Placement and Soldering

Accurate component placement and proper soldering techniques are critical aspects of PCB assembly inspection. Ensuring correct alignment, secure connections, and sufficient solder joint quality greatly reduces the risk of defects. Thoroughly inspect all solder joints, checking for issues such as bridging, cold solder, and insufficient solder volume.

6. Verify Electrical Continuity

Verifying electrical continuity is an essential step in PCB assembly inspection. Ensure that all required connections and conductive paths are intact and correctly established. Test for shorts, opens, and other issues using appropriate testing equipment, such as a multimeter or continuity tester.

7. Document and Record Inspection Results

Proper documentation and record-keeping are crucial for effective PCB assembly inspection. Maintain a comprehensive inspection log that includes details such as inspection date, component details, testing results, and any defects identified. This documentation helps track trends, analyze data, and identify areas for continuous improvement.

Conclusion

In conclusion, understanding and implementing effective PCB assembly inspection techniques are essential for ensuring the quality and reliability of electronic devices. By following the tips provided in this guide, you can streamline your inspection process and minimize the risk of defects and failures. Remember to continuously update your knowledge, invest in advanced inspection equipment, and conduct regular quality control audits to optimize your PCB assembly inspection procedures.

At Luxury Ride Dubai, we offer a wide range of luxury car rental options to enhance your visit to Dubai. From Audi R8 Coupe V10 to Lamborghini Urus and Mercedes G63 AMG, our fleet is designed to provide you with an unforgettable driving experience. Contact us today to book the luxury car of your dreams!