Shelf Life of Soldered Components

Products

Soldered Components and Their Lifespan

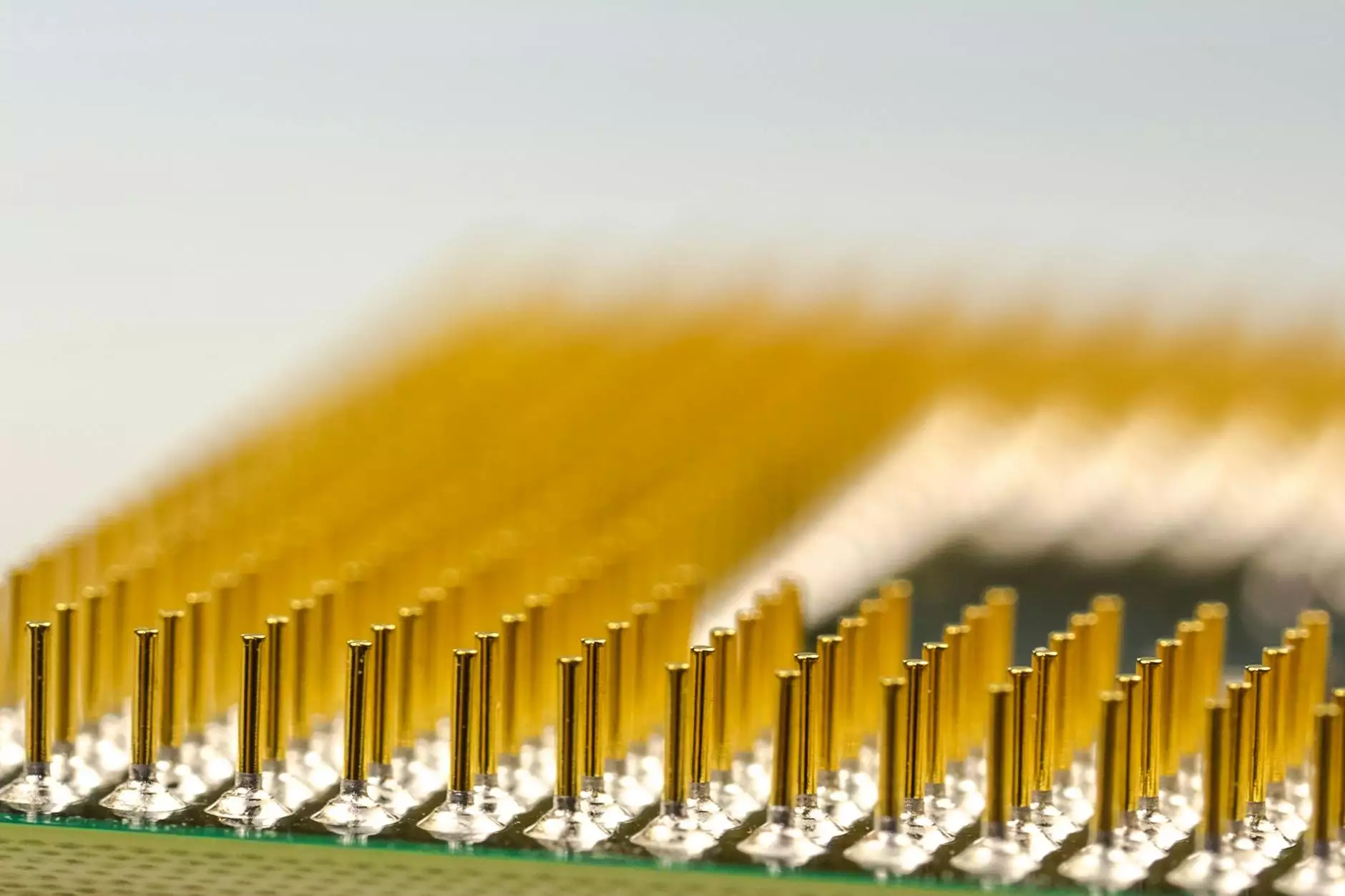

Soldered components are vital in various industries, including the manufacturing of electronic devices, automotive systems, and aerospace equipment. Understanding the shelf life of soldered components is crucial to ensure their functionality and reliability.

What is the Shelf Life of Soldered Components?

The shelf life of soldered components refers to the period during which these components can be stored without significantly affecting their performance and solderability. It is essential to assess the shelf life of soldered components to ensure their long-term usability.

Factors Affecting the Shelf Life of Soldered Components

The shelf life of soldered components can be influenced by several factors, including:

- Humidity and moisture exposure: High levels of humidity can lead to oxidation and corrosion, damaging the solder joints.

- Temperature: Extreme temperatures can cause thermal stresses, leading to the degradation of soldered connections.

- Contaminants: Dust, dirt, and chemical residues can negatively impact the integrity of soldered components.

- Time: The longer soldered components are stored, the greater the chance of degradation and reduced performance.

Best Practices for Extending Shelf Life

To extend the shelf life of soldered components, consider implementing the following best practices:

Storage Environment

Ensure that the storage environment is clean, dry, and free from contaminants. Maintain the temperature within the recommended range, typically between 15°C and 30°C.

Proper Packaging

Use appropriate packaging materials, such as moisture barrier bags or vacuum-sealed containers, to protect soldered components from moisture and oxidation.

Desiccants

Include desiccant packs or humidity indicator cards in the packaging to absorb any moisture that may enter the storage environment.

First-In, First-Out (FIFO) Rotation

Adopt a FIFO rotation system to ensure that older stock is used before newer stock, minimizing the chances of components becoming outdated or degraded.

Regular Inspections and Testing

Periodic inspections and testing of soldered components are essential to identify any signs of degradation or potential issues. This practice helps ensure that only reliable components are used in final products or assemblies.

Consult with Experts

If you have specific concerns or questions about the shelf life of soldered components, it is advisable to consult with experts in the field. They can provide tailored recommendations based on your industry and application requirements.

Conclusion

Understanding the shelf life of soldered components is crucial for industries relying on their performance and reliability. By implementing best practices for storage, packaging, and regular inspections, you can extend the shelf life of soldered components and ensure their optimal functionality. For personalized advice, reach out to industry experts who can guide you through specific considerations.