Leading CNC Precision Turning Parts Manufacturers in China

In today's rapidly evolving industrial landscape, the demand for high-quality, precision-engineered components is greater than ever. China CNC precision turning parts manufacturers have established themselves as leaders in the field, providing cutting-edge solutions tailored to meet a variety of industrial needs. This article delves into the importance of precision turning, the capabilities of these manufacturers, and the myriad benefits they offer to businesses globally.

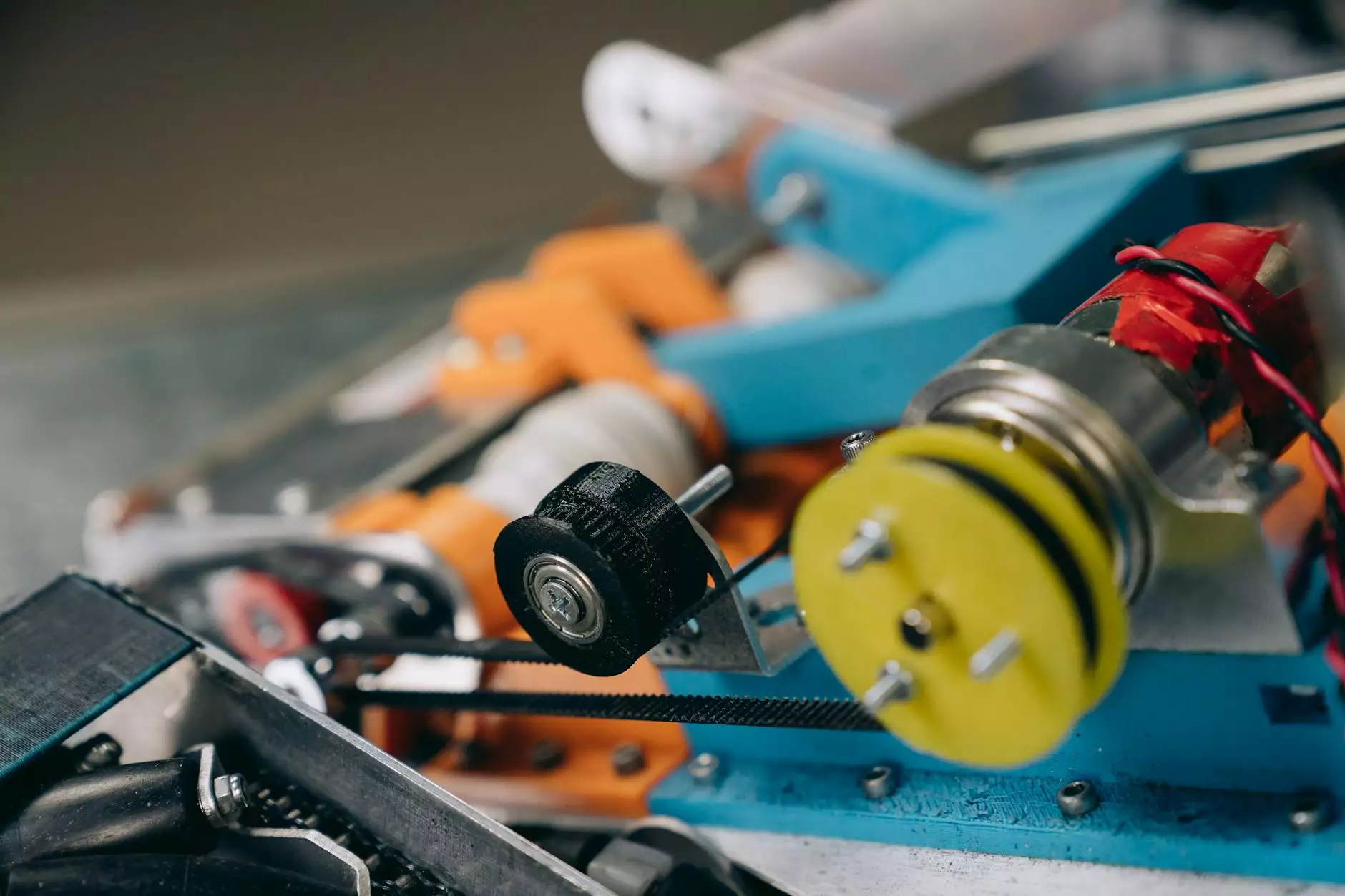

Understanding CNC Precision Turning

CNC (Computer Numerical Control) precision turning is a manufacturing process that involves the controlled rotation of a workpiece against a cutting tool to produce intricate and precise components. This process is fundamental in several industries, including aerospace, automotive, electronics, and medical devices. Precision turning ensures that parts are not only produced at a high volume but also maintain exact specifications to meet the rigorous demands of modern engineering.

The Role of China’s CNC Precision Turning Parts Manufacturers

China CNC precision turning parts manufacturers are at the forefront of revolutionizing precision engineering. Their extensive expertise, advanced technology, and a commitment to quality make them indispensable to various sectors. Here are some key aspects that highlight their critical role in the global manufacturing supply chain:

- Advanced Technology: Utilizing state-of-the-art CNC machinery, Chinese manufacturers can achieve unparalleled accuracy and efficiency in production.

- Innovation: Continuous investment in research and development leads to innovative solutions that meet the evolving needs of industries.

- Quality Assurance: Stringent quality control processes ensure that every part meets the highest industry standards.

- Resource Availability: With access to a wide range of raw materials and advanced manufacturing techniques, these manufacturers can produce a variety of components.

The Advantages of Partnering with Chinese Manufacturers

When businesses choose to source their CNC precision turning parts from Chinese manufacturers, they unlock a multitude of benefits. Below are some of the top advantages that make these manufacturers a preferred choice.

1. Cost Efficiency

One of the most significant advantages is the cost-efficiency that Chinese manufacturers offer. With competitive labor costs and streamlined production processes, companies can reduce their manufacturing expenditures significantly. This allows businesses to allocate resources more effectively, enhancing overall profitability.

2. Scalability

As businesses grow, their manufacturing needs can change dramatically. Chinese manufacturers excel in scalability—they can ramp up production quickly to accommodate increased demand without sacrificing quality. This flexibility is crucial for companies looking to expand their product lines or enter new markets.

3. Expertise and Specialization

Many CNC precision turning parts manufacturers in China have decades of experience in metal fabrication and precision engineering. Their expertise allows them to handle complex designs and materials that may be challenging for less experienced manufacturers. This specialization ensures that clients receive parts that meet intricate specifications.

4. Quick Turnaround Times

In a competitive market, time is of the essence. Chinese manufacturers are known for their quick turnaround times, enabling businesses to meet project deadlines and launch products to market faster than their competitors. This efficiency is achieved through optimized production schedules and advanced logistics.

Key Industries Utilizing CNC Precision Turning Parts

The applications of CNC precision turning parts span a wide array of industries. Understanding these applications can help businesses identify how they can leverage precision turning in their operations. Here are some key industries benefiting from precision turning technology:

- Aerospace: Components such as turbine blades, housings, and brackets are manufactured with exceptional accuracy to meet stringent safety standards.

- Automotive: Critical engine parts, transmission components, and suspension elements are produced to enhance performance and reliability.

- Electronics: Precision turned parts in electronic devices contribute to the overall functionality and design of products like smartphones and computers.

- Medical: High-precision components for medical devices require immaculate detail to ensure safety and performance in life-saving applications.

Choosing the Right Manufacturer

With a plethora of CNC precision turning parts manufacturers in China, selecting the right one can be daunting. Here are some factors to consider when evaluating potential manufacturing partners:

1. Certifications and Standards

Ensure that the manufacturer holds relevant certifications, such as ISO 9001, which indicates a commitment to quality management systems. Adherence to international standards guarantees that the parts meet strict quality requirements.

2. Industry Experience

Consider the manufacturer’s experience in your specific industry. A manufacturer with a proven track record in your sector will be more familiar with the complexities and regulatory requirements of your projects.

3. Technology and Equipment

Investigating the types of CNC machinery and technology that the manufacturer employs is crucial. Advanced equipment allows for higher precision and efficiency, directly impacting the final product quality.

4. Customer Reviews and Case Studies

Look for testimonials and case studies from previous clients. Positive feedback and successful projects can provide insights into the manufacturer’s reliability and capability.

Future Trends in CNC Precision Turning

The landscape of CNC precision turning is constantly evolving. As technology advances, new trends emerge that shape the industry. Here are some key trends to watch for in the near future:

- Automation: Increased use of automation in CNC machines will enhance efficiency and reduce the risk of human error, resulting in even higher quality parts.

- Industry 4.0: The integration of IoT (Internet of Things) technology into manufacturing processes will facilitate real-time monitoring and predictive maintenance, leading to optimized production.

- Advanced Materials: As new materials are developed, CNC precision turning will evolve to meet the challenges and opportunities presented by these innovations.

- Sustainability: A growing emphasis on sustainable manufacturing practices will lead to the adoption of eco-friendly processes and materials.

Conclusion

In conclusion, China CNC precision turning parts manufacturers play a pivotal role in modern manufacturing across various industries. Their commitment to innovation, cost efficiency, and high-quality production ensures that they remain at the forefront of precision engineering. Businesses looking to enhance their manufacturing capabilities should consider partnering with these manufacturers, leveraging their expertise to achieve exceptional results in product quality and overall performance. By understanding the importance of CNC precision turning and making informed choices about manufacturing partners, companies can secure a competitive edge in their respective markets.

For more information about top-tier manufacturing services, visit Deep Mould, where quality and precision meet innovation.